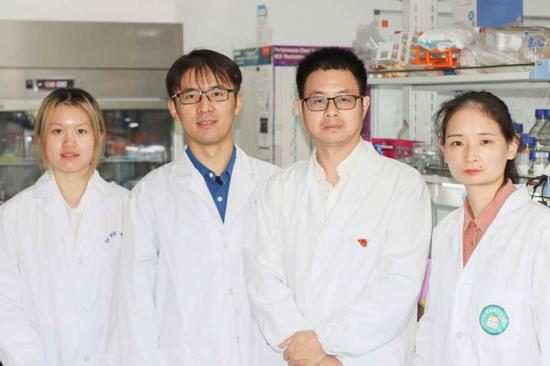

A Samsung Display researcher analyzes the optical properties of quantum dot ink in this handout photo released Monday. Courtesy of Samsung Display By Nam Hyun-woo Samsung Display said Monday it has succeeded in recycling quantum dot (QD) ink for the first time in the industry, allowing for an annual cost savings of at least 10 billion won ($7.2 million).

According to the company, it has been using recycled QD ink for its mass production line since October, by reclaiming and reprocessing 80 percent of the ink wasted in the production of the QD light-emitting layer. QD light-emitting layer is the key structure of QD-OLED displays and is manufactured through inkjet printing that densely sprays red and green QD ink through micro-size nozzles. In this process, however, approximately 20 percent of the total QD ink used in the process is left over in the nozzles and discarded.

Samsung Display said it formed a task force to improve the efficiency of QD ink last December, and successfully developed QD ink recycling facilities in August. The company said the recycled ink undergoes an advanced synthesis process to enhance purity and optical properties, achieving the same performance as the original ink in quality tests. “With Samsung Display’s QD-OLED receiving rave reviews, we are using more QD ink than ever before,” Samsung Display Vice President Kim Seong-bong said.

“By developing the technology that recycles QD ink within our domain, we will be able to save costs significantly and contribute to recycling resources.” Samsung Display said it plans to enhance its competitiveness in manufacturing QD-OLED further, by improving equipment performance and process capabilities to increase productivity and yield..